About Us

About Us

Prometal Galvano was established in 2004 to serve in Surface Treatment Technologies and Automatic Plating Lines.

At the beginning of production life, we gained experience by serving different sectors. Since 2008, we have expanded our investments and moved to the existing production area of 2,000 square meters in order to provide better service to our customers.

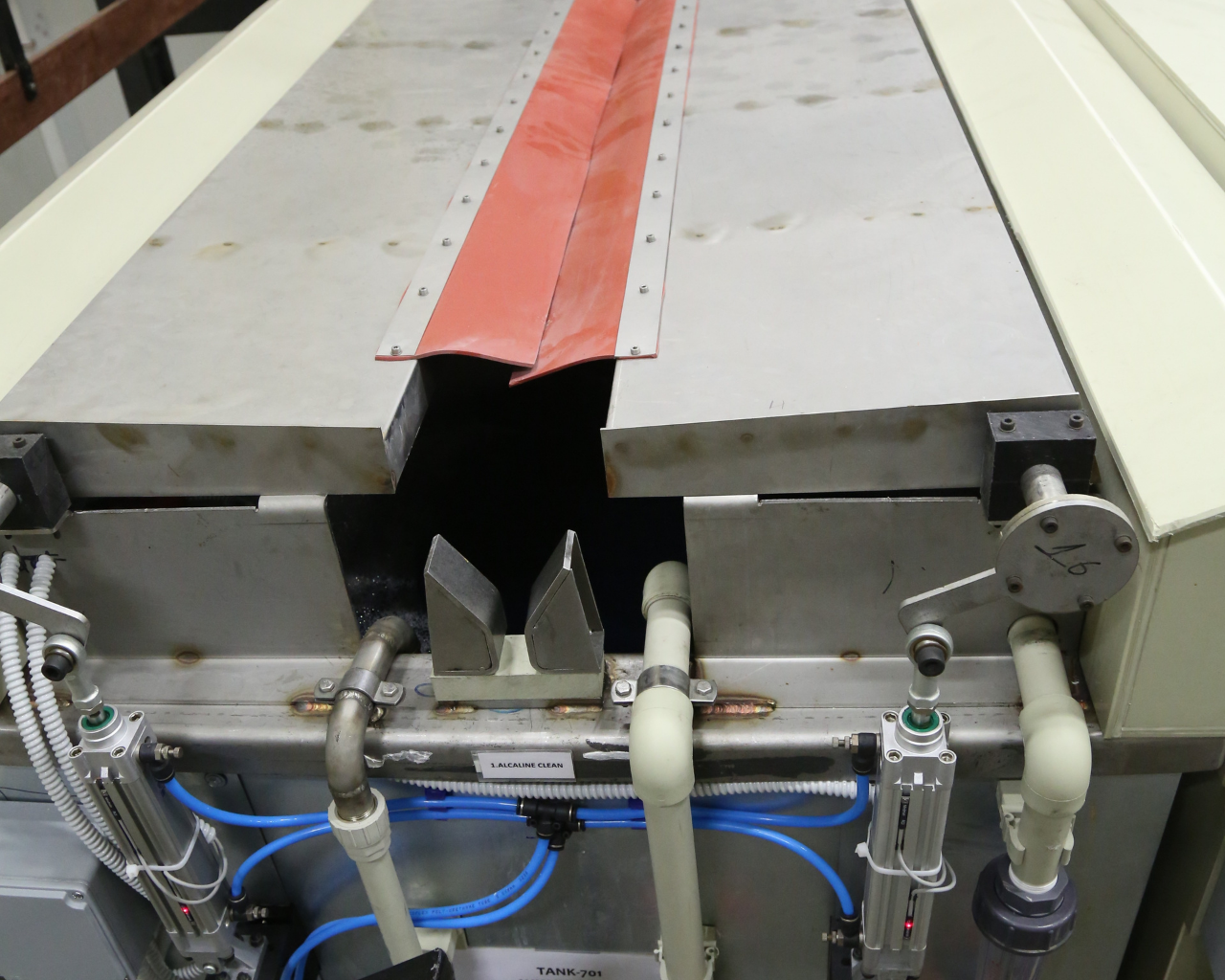

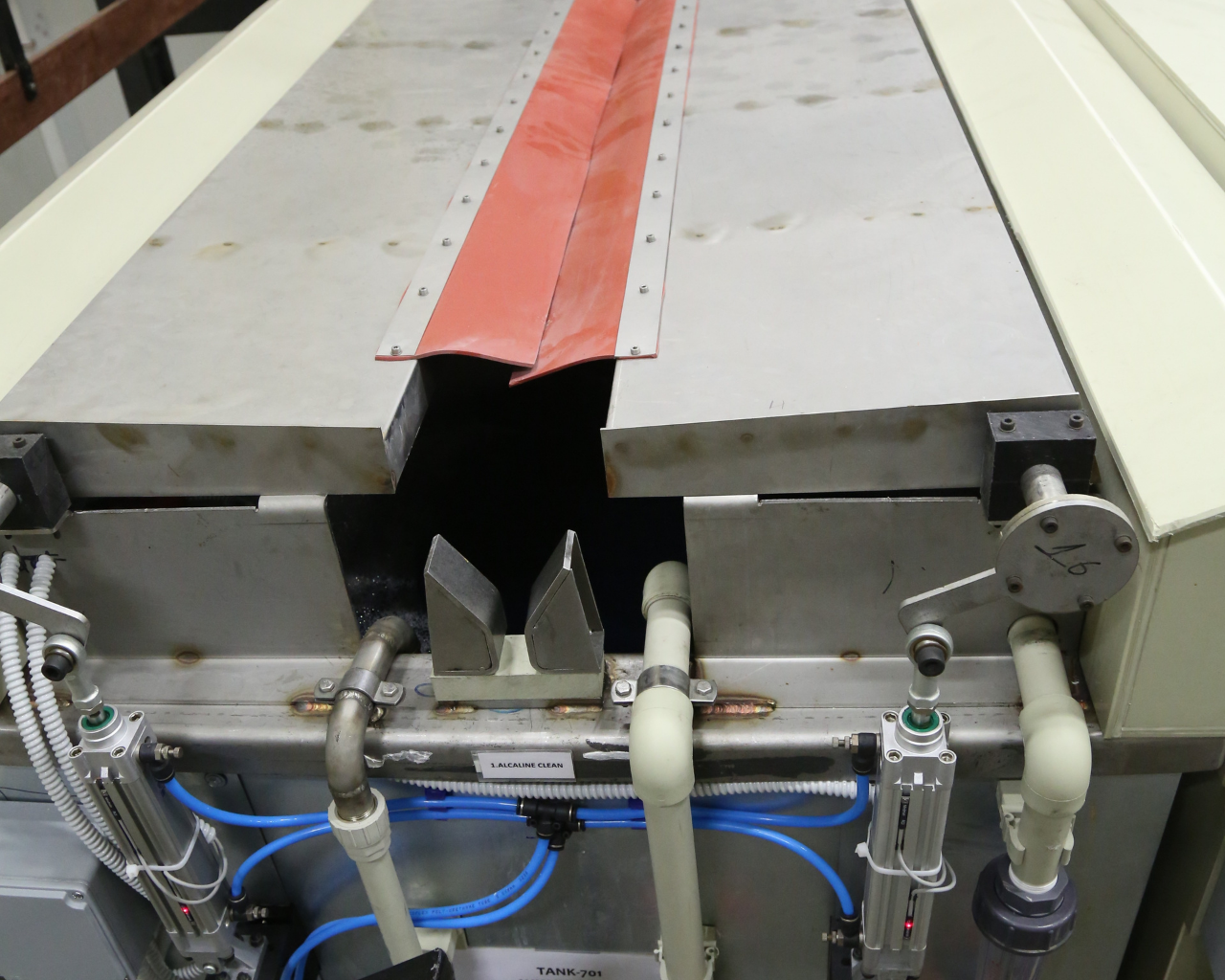

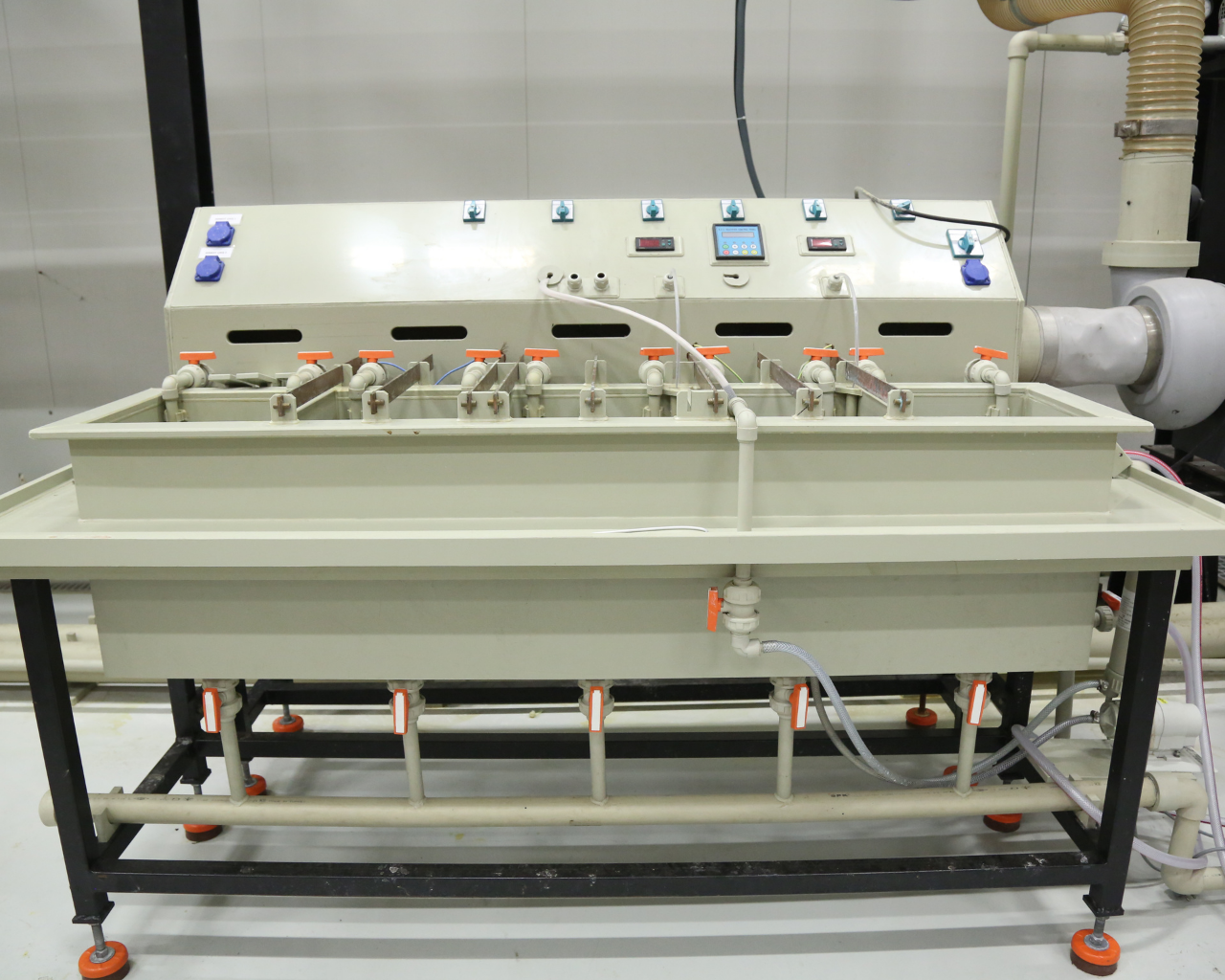

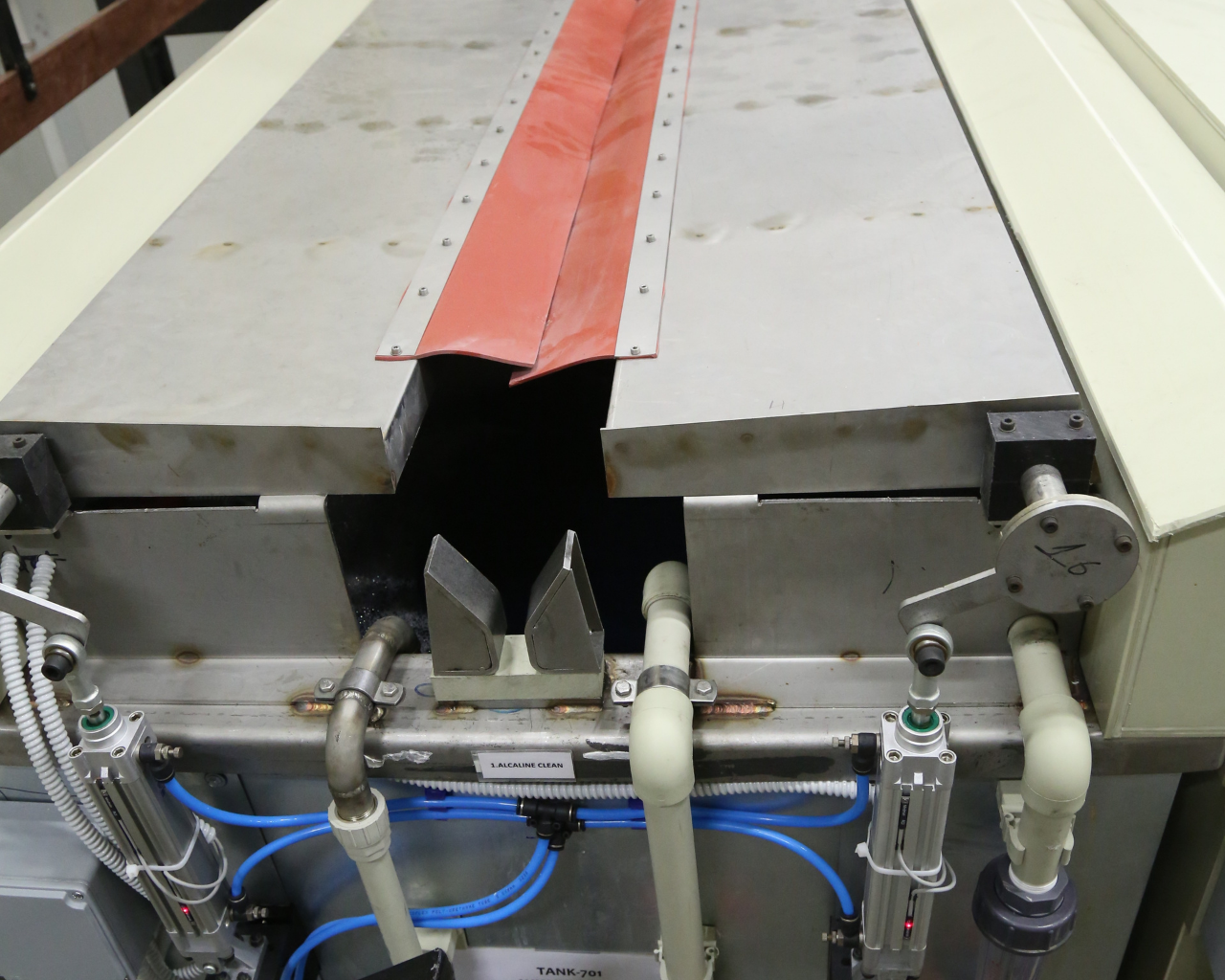

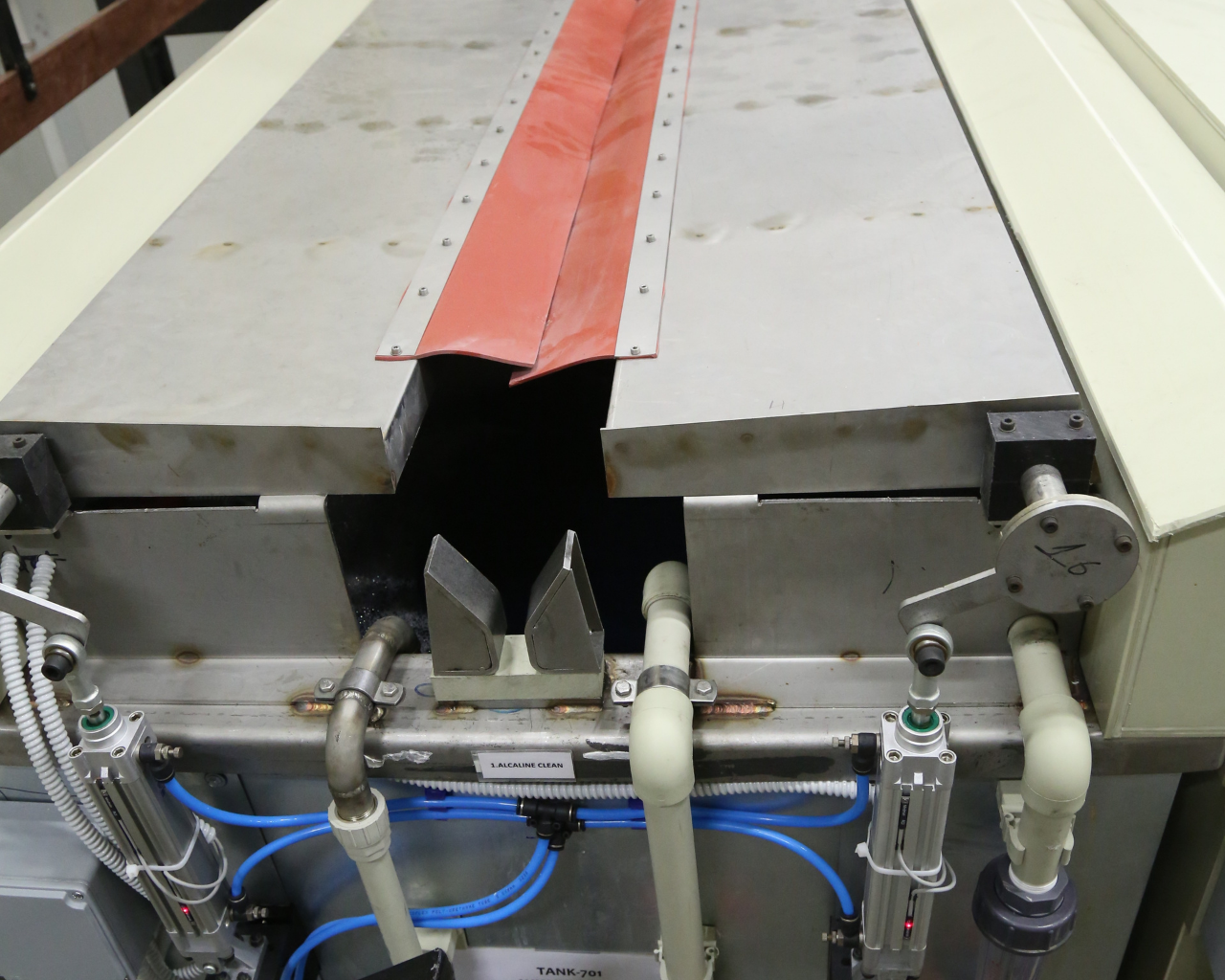

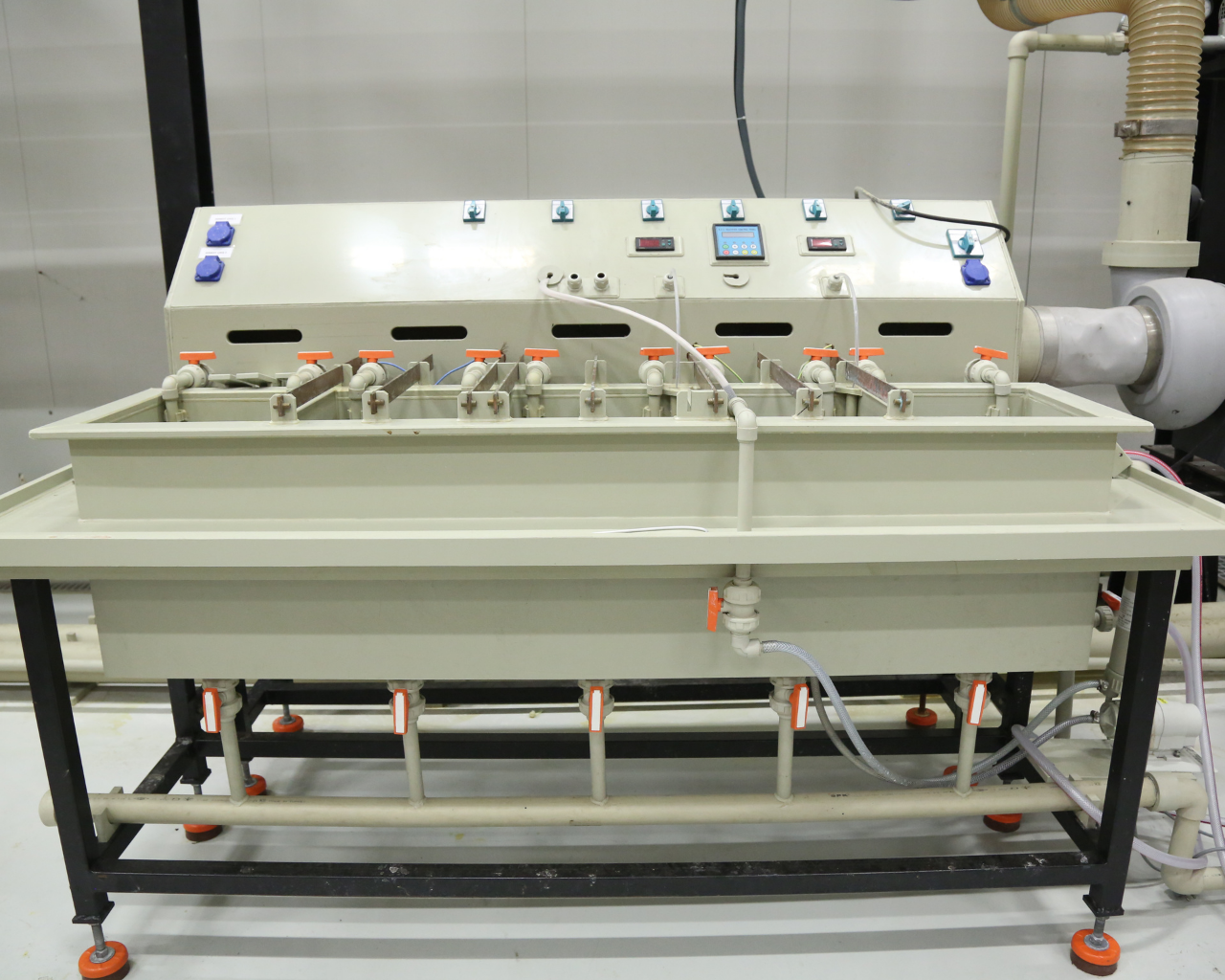

Since the new period, we have established different plants such as Zinc & Alkali Zinc, POP Facilities, Nickel+Chrome Facilities for Automotive and White Goods, as well as special processes and hard anodizing for the aviation industry. With these plants, we gained serious experiences abroad especially in Uzbekistan, Canada, America, Greece and Bulgaria. Using this experience, we design the plants to ensure the sustainability of the targeted capacity with a customer and efficiency optimization-oriented approach.

Although it is not noticed in our daily life, it is possible to see the impact of the Galvano Sector all over life. We are increasing our development day by day and are on our way to become a sought-after and preferred brand in both local and international markets in Surface Treatment Sector.

Our aim is not only to succeed, but to take part in life as a whole.

01.

We Are Listening

Sharing technical data with us in parallel with the request from our potential customer

02.

We Design For You

Creation and implementation of the workflow diagram in the light of the technical data received. Creating a simple 2-dimensional layout plan in parallel with the creation of the technology and accessory table related to the project in line with our work flow chart and then holding the meeting, finalizing the presentation file and proposal in line with the result of the meeting

03.

Custom Design For Your Needs

As a result of mutual agreement, 3D design and all details of the project should be removed, production phase should be started and shipment and assembly procedures should be performed with the completion of production, approval tests should be performed as a result of commissioning of the project and the project should be delivered.